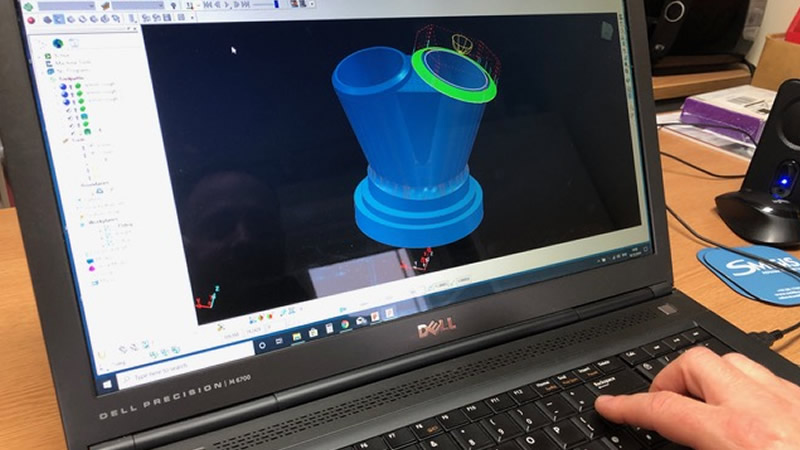

As part of our commitment to quality and efficiency, JM Automatics have invested in the latest CAD/CAM tools, providing off-line programming and validation of programs prior to CNC machining.

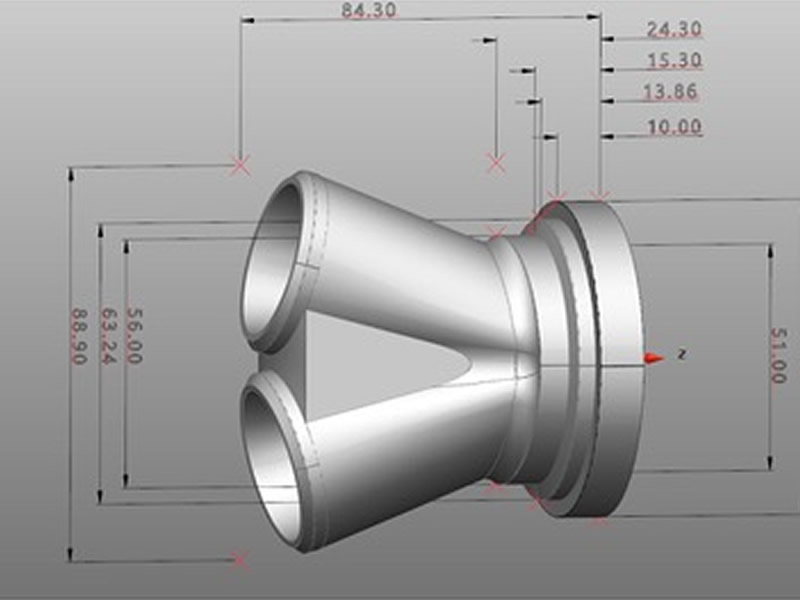

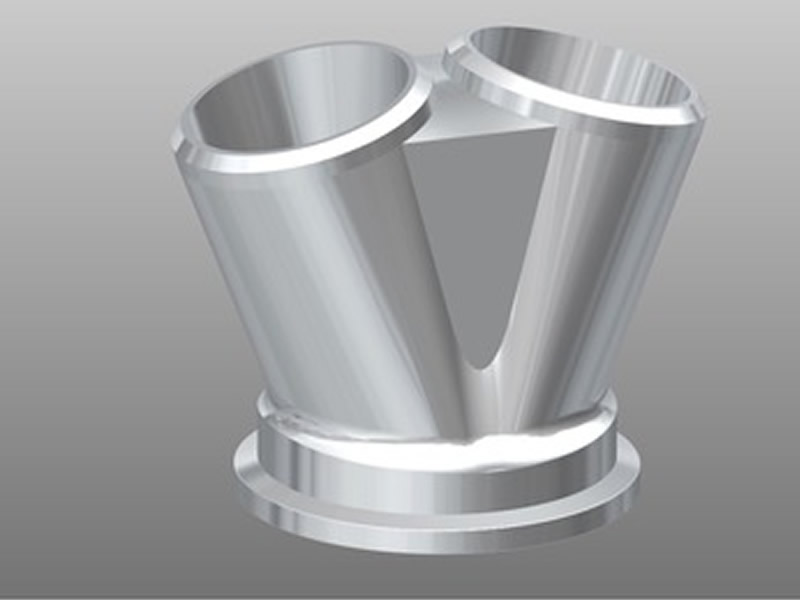

We have the capability to work with full and part 3D customer supplied models. This data can be used to create a machine programme and finally for inspection utilising our co-ordinate measuring machine and state-of-the-art laser enabled Faro and Romer inspection arms.

CAD/CAM allows machining programs to be fine-tuned to maximise efficiency and minimise waste in the production process, ensuring smooth operation, elimination of errors and most importantly on-time product delivery.